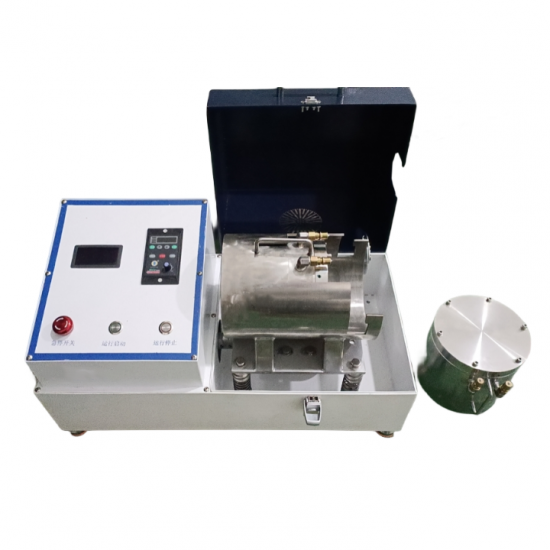

Lab 50ML-1000ML Vibratory Ball Grinding Mill Machine

The vibrating ball mill is driven by the motor through the winding coupling to produce vibration of the shaft equipped with eccentric block, which is transmitted to the stand. The stand is equipped with a ball mill cylinder, so the powder follows the vibration. Both sides and the bottom of the stand are equipped with springs connected to the machine base. Observed from the end surface of the ball mill cylinder, the trajectory of any powder body is a flat and curved. The height of the powder jumping is equal to 2 times the amplitude, the movement is mainly vibration, but due to inertia there is also a small amount of rotation.

Applications

Vibrating ball mill is the crushing equipment used in mineral processing and powder metallurgy, which is widely used in ceramics, non-metallic minerals, pigments, electronics, chemical industry, metallurgy, building materials, new materials, food and pharmaceuticals. It is used for fine crushing, the efficiency is 2 times higher than the general ball mill, has the advantages of simple structure, low cost and so on.

Parameters

Model

JT-ZM-1L

Reference external size (mm)

600X320X420

Weight (KG)

35KG

Vibration motor power

150W

Amplitude (mm)

5-8

Frequency (r/min)

3000(Variable frequency adjustable)

Ball milling jar volume

50ML-1000ML

Feeding particle size (mm)

<5

Discharge particle size(mesh)

200-2000(Related to material properties)

Material of ball milling jar

Stainless steel, agate, zirconia, tungsten carbide

|

Model |

JT-ZM-1L |

|

Reference external size (mm) |

600X320X420 |

|

Weight (KG) |

35KG |

|

Vibration motor power |

150W |

|

Amplitude (mm) |

5-8 |

|

Frequency (r/min) |

3000(Variable frequency adjustable) |

|

Ball milling jar volume |

50ML-1000ML |

|

Feeding particle size (mm) |

<5 |

|

Discharge particle size(mesh) |

200-2000(Related to material properties) |

|

Material of ball milling jar |

Stainless steel, agate, zirconia, tungsten carbide |

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported