Perovskite Solar Cell Research Lab Fabrication Plant

Process and equipment required

|

Process |

Equipment Name |

Model |

Website Link |

|

Solution Preparation |

Magnetic stirrer |

TMAX-SC-MS-I |

|

|

Planetary centrifugal mixer |

TMAX-ITT-300SS |

||

|

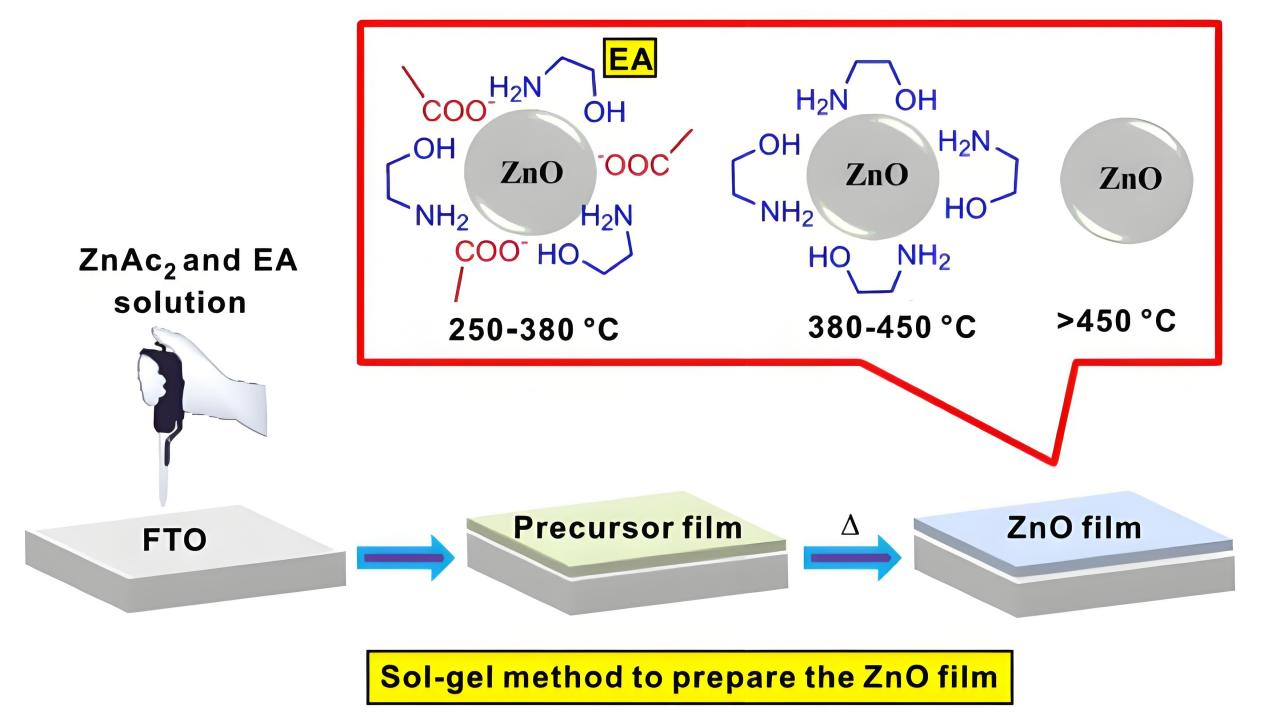

TiO2 Coating |

Vacuum Spin Coater with Plate Holder |

TMAX-4A |

|

|

DC or RF High Vacuum Magnetron Ion Sputter |

TMAX-650MH |

||

|

Perovskite Coating

|

Bench-Top Ultrasonic Spray Pyrolysis Coating Unit with 6"×6" Heating Plate up to 500C |

TMAX-MSK-USP-02 |

|

|

Vacuum Slot Die Coating Machine

|

TMAX-MSK-AFA-PD100 |

||

|

Spiro-OMeT AD Coating |

Vacuum Spin Coater with Plate Holder |

TMAX-4A |

|

|

Slot die coater |

TMAX-SC-SD-I |

||

|

IZO Coating

|

Liquid crystal screen magnetron sputtering instrument |

TMAX-SC-SU-I

|

|

|

Film Rolling

|

Lab Hot Roll Press Calender Machine for Rolling Coated Substrate |

TMAX-DG |

|

|

Automatic hot press with multi-segment programming function |

TMAX-RYJ-600ZG |

||

|

Substrate Cleaning |

Ultraviolet ozone cleaning machine |

TMAX-SC-UV-I

|

|

|

Plasma cleaning machine |

TMAX-SC-PE-I |

||

|

Film Drying

|

High specification vacuum dryer(Equivalent to the ossila brand in the United States) |

TMAX-SC-H-II |

|

|

Note: Substrate cleaning can be divided into pre-coating cleaning and post-coating cleaning: Uv ozone cleaning machine is used to remove impurities on the surface of the substrate, and the developer is usually used for cleaning after spin coating (this step requires the use of automatic glue dropping function and liquid leakage function).

Dryer is the customer after spinning coated the sample, put the sample into the dryer to make the film rapid molding, this can be based on customer needs, usually the solution viscosity of high film can be quickly formed without the need to use the dryer, the solution viscosity is thin difficult to form a film, you need to use the dryer. |

|||

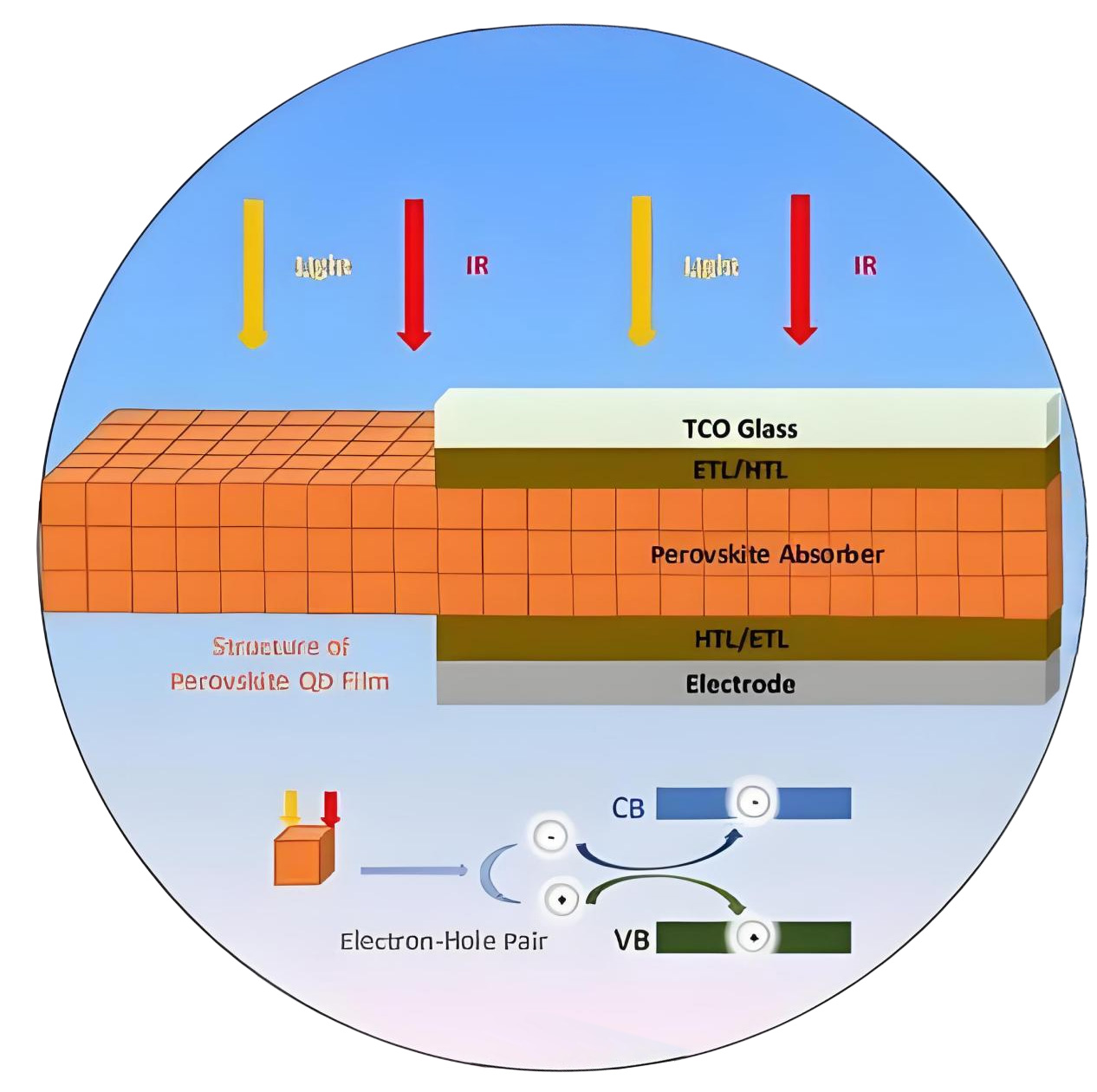

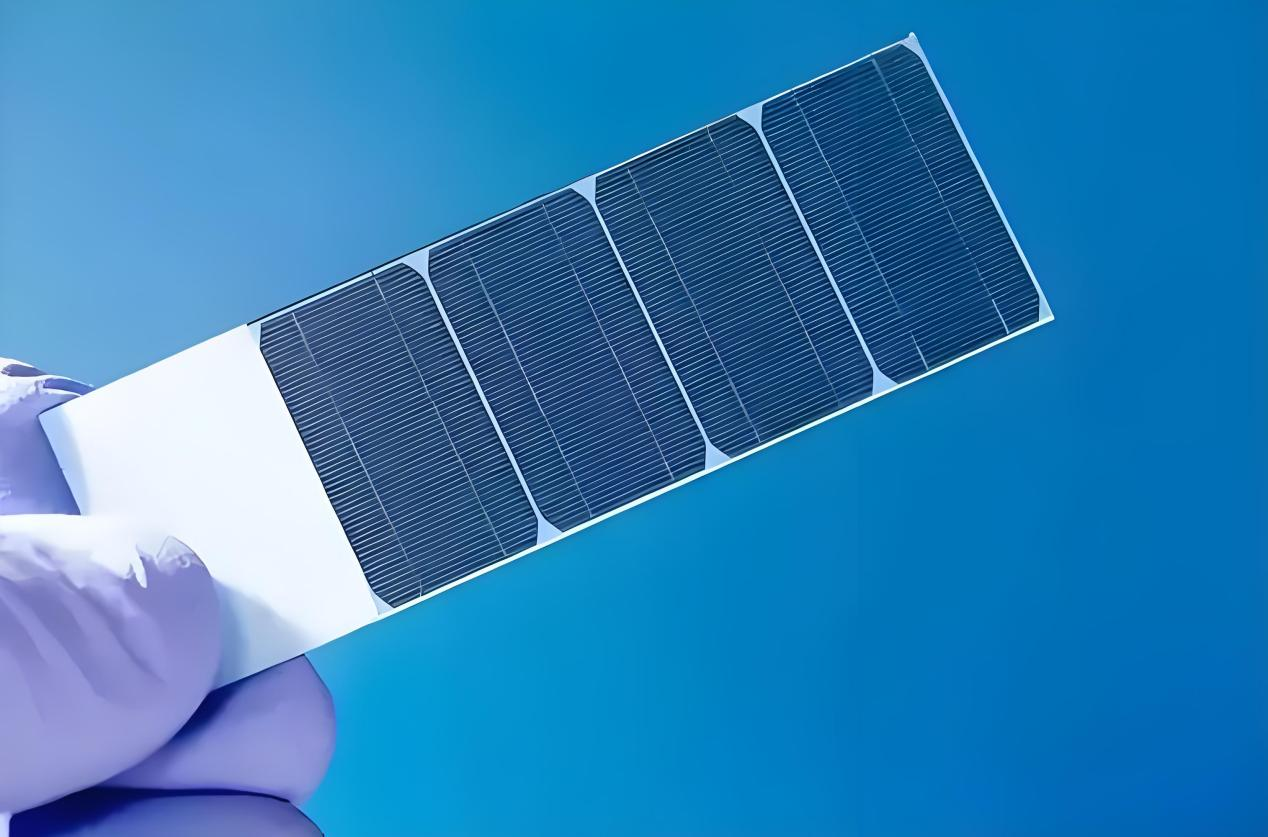

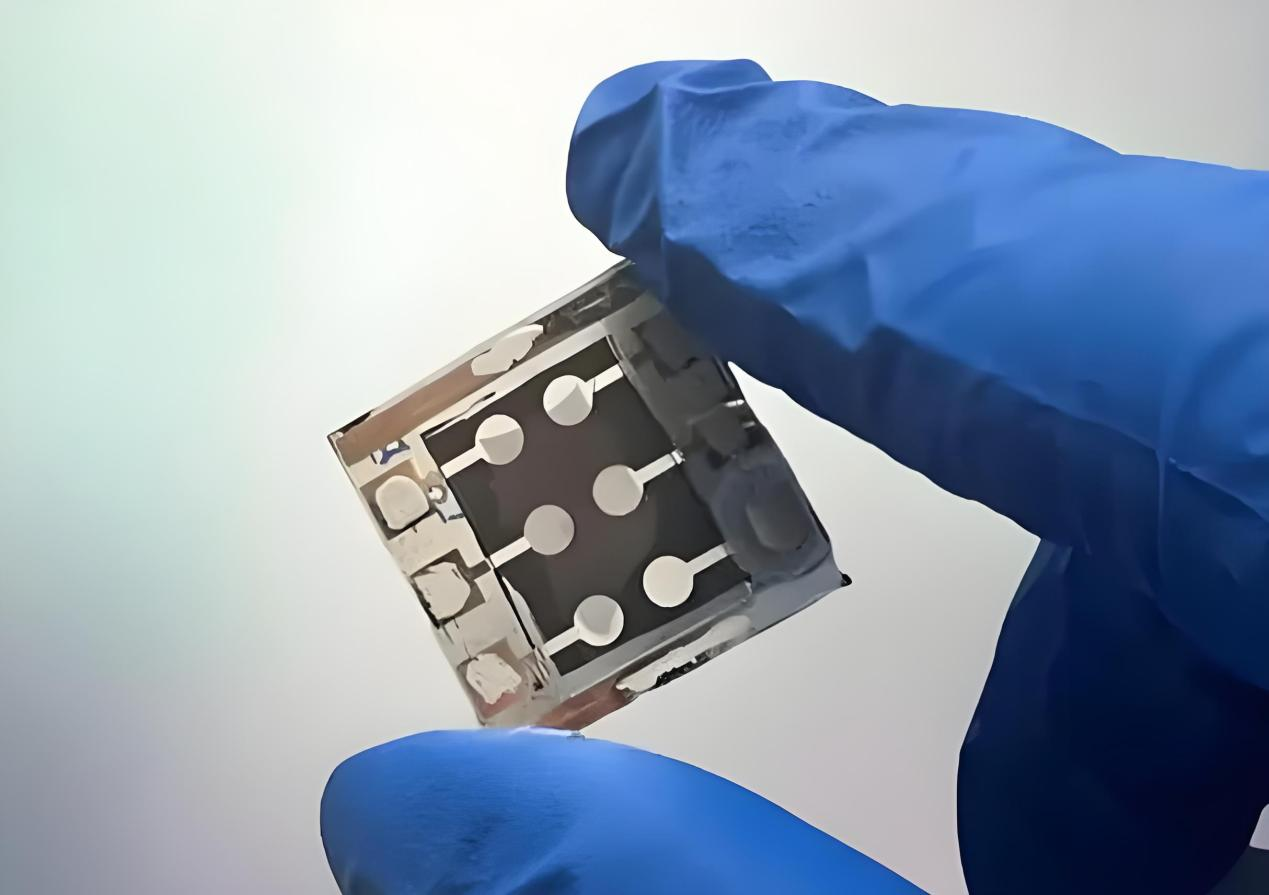

Application field

Applications for perovskite batteries include buildings, mobile devices, wearables, transportation, outdoor and camping activities, remote areas and developing countries.

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported