Vacuum Magnetron Ion Sputtering Coating Coater for

Semiconductors and Battery

Introduction

Magnetron Ion Sputtering Coater (SD900M Model) is ideal and designed for lab SEM sample preparation. It is widely used to coat non-conductive or heat-sensitive SEM samples with Au for better imaging. It is also excellent for surface treatment and avoids damage to the substrate sample.

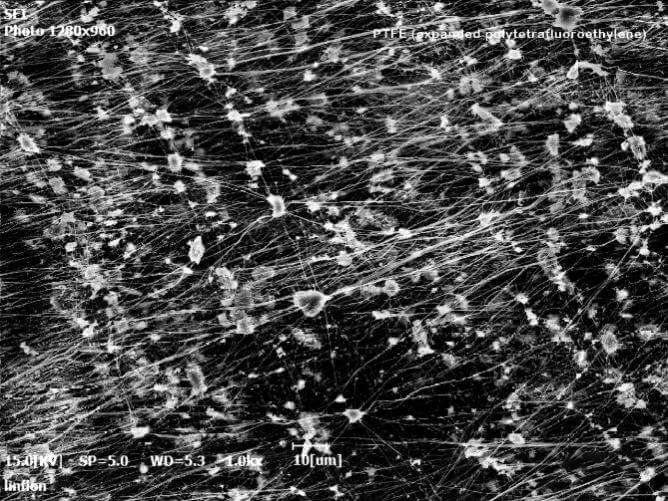

Coating Result Sample Picture under SEM (by SD-900M Model) EPTFE (Extended Poly Tetra Fluoro Ethylene)

Low vacuum, can be achieved quickly when using proper vacuum pump within 5 minutes. It generates much less heat and avoids plasma damage to the substrate sample. It is user friendly and easy to operate.

Vacuum pump is included. Chiller is optional.

Parameter

|

Vacuum pump set |

(Oil required) rotary vacuum pump |

|

Rotary pumping speed |

50 Hz : 8 m³/h (2.2 L/s)/ 60 Hz : 9.6m³/h (2.6 L/s) |

|

Vacuum limit |

2 Pa |

|

Max sputtering current |

100mA |

|

Working pressure |

20Pa - 8 Pa |

|

Vacuuming time |

<5 Min(2 Pa) |

|

Vacuum measure |

Measuring range from atmosphere to 2*10-2mbar |

|

Chamber size |

Φ150*120mm (height) scratch resistant quartz glass |

|

Magnetron target source |

Target size φ50*0.1mm(Au)/target source: Au,Ag,Pt |

|

Operation method |

Instruction Manual |

|

Weight/size |

45kg/360mm length x 300mm wide x 380mm high |

|

Power supply |

AC 110V 60Hz or AC 220V 50Hz |

|

Power consumption |

<1500W |

|

Cooling method |

Water cooling(optional) |

|

Warranty |

One year limited warranty with lifetime product support |

Tel : +86-592-3926659

Tel : +86-592-3926659 Email : gilia@inthelaboratory.com

Email : gilia@inthelaboratory.com

IPv6 network supported

IPv6 network supported